Introduction of Sapphire

α-Al2O3 single sapphire is another name corundum, is a simple ligand-type oxide crystals. Sapphire owns excellent properties in optics, machining, and chemical stablibility. Also it is a material with performance of high strength, high hardness, and high wear resistance. Sapphire can work functional under 2000℃. With these properties, it is widely used in IR window material for military devices, satellite space technology, and high-intensity laser.

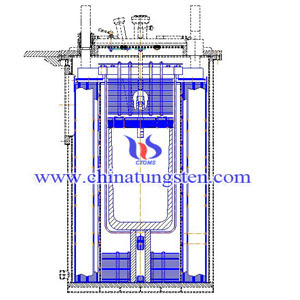

Tungsten and molybdenum crucibles used as carrier of sapphire crystal growth, are important parts in thermal field. Tungsten and molybdenum crucibles are set in the middle of thermal field. Sapphire crystal are growing in the crucibles. The main reason to use tungsten and molybdenum as material for crucible is its high temperature resistance property. The melting point of tungsten is 3420℃, and molybdenum 2610℃. With this property, it can make sure for the purity of sapphire crystal, and prevent them from foreign elements.

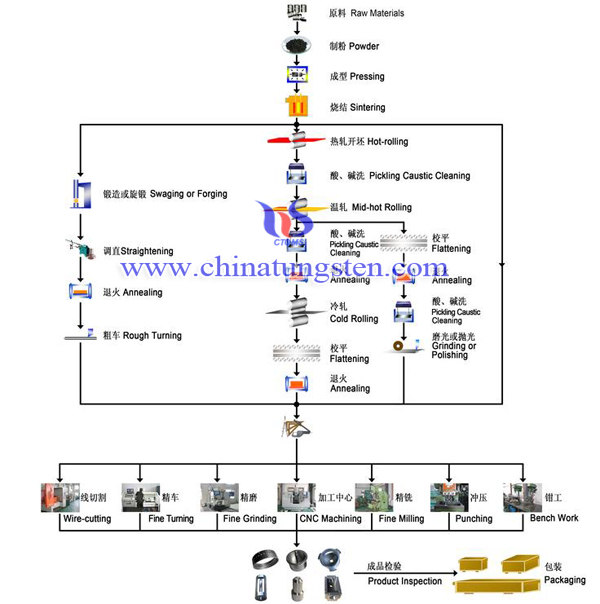

Manufacturing process of tungsten and molybdenum are very similar.

For tungsten crucible, tungsten powder used as raw material, under mold, and then pressing powder to crucible shape. After that, sintering crucible, and surface treatment. For molybdenum, the material is changing into molybdenum powder. And both tungsten and molybdenum crucible are manufactured from powders with purity over 99.95%.

Email:sales@chinatungsten.com

Tel.:+86 592 512 9696

Fax:+86 592 512 9797

|